What is it? And what is its potential? We asked Trailer Dynamics.

The trucking industry operates a wide range of vehicles that carry all types of goods over various distances, from busy urban centres to isolated rural areas. To decarbonise the road transport sector while continuing to deliver efficient services, a wide range of solutions are required.

The IRU Green Compact’s evidence-based approach to decarbonisation leverages two sets of solutions at the same time – efficiency measures and alternative fuels – for the sector to become carbon neutral in the most cost-effective way, maintaining resilience and the ability to meet future demand.

Efficiency measures cover logistics (retiming, route optimisation and eco-trucks), vehicles (tyres, lightweighting and advanced lubrication) and drivers (eco-driving, skills monitoring and certification schemes).

In parallel, the industry needs to be supported by a robust, practical and economic transition to alternative fuels. This means investing now in fossil-free alternative fuels, including electricity, hydrogen and biofuels, as well as the public and private infrastructure, vehicles and operational practices needed to use them.

We asked Michael W. Nimtsch, Co-founder and Managing Director of IRU member Trailer Dynamics, to unpack an emerging solution that touches on both efficiency measures and alternative fuels: battery swapping.

What is battery swapping?

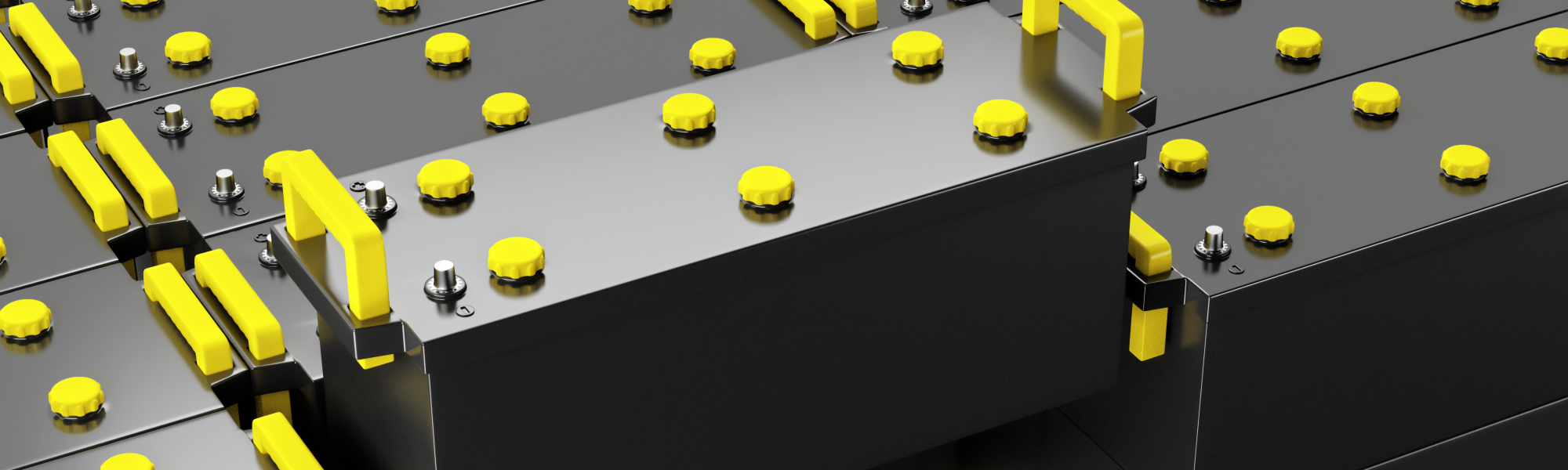

Battery swapping is a system whereby trucks and trailers can replace their depleted batteries with fully charged ones at depots or swapping stations.

Together with DB Schenker and the Contemporary Amperex Technology Co Ltd (CATL), we are currently conducting a feasibility study for the creation and implementation of battery-swapping stations capable of servicing the future needs of electrified trailers and potentially electrified trucks across Europe.

Why are you exploring battery swapping?

When we talk about technology openness, we can’t limit ourselves to powertrain and energy sources. It’s also vital to explore charging alternatives.

Stationary charging and inductive charging are familiar options, but battery swapping is an emerging technology for electrified road goods transport.

Battery swapping offers several significant advantages. Firstly, it greatly increases the efficiency of electrified fleets. Charging time is reduced from three hours to just five minutes. This remarkable reduction allows for much higher fleet efficiency.

Users benefit from always having a fully charged and well-maintained battery. Additionally, they can choose the battery capacity that suits their operations.

Acquisition costs for vehicles are lowered since battery purchase costs are charged on a pay-per-use basis. Users only pay for what they need.

Moreover, the space required for charging electrified heavy-duty vehicles is significantly reduced compared to traditional stationary charging stations. It also lowers reliance on conventional charging infrastructure.

Overall, these advantages mean that more trucks and trailers are available.

What is stopping the industry from implementing battery swapping?

The primary challenge lies in creating the first prototype in Europe. This involves securing financing and assembling partner companies for the project. In the future, we aim to expand the group of participating companies and include more logistics firms, energy suppliers and service providers.

Fortunately, the technological challenges are manageable. Battery-swapping stations already exist in China, demonstrating the concept's feasibility. Additionally, CATL has developed compatible battery designs. The vehicle configuration is technically sound from an engineering perspective.

CATL will adapt its battery expertise to fit Trailer Dynamics’ eTrailers. They will also provide essential technical data for designing battery-swapping stations.

Meanwhile, Trailer Dynamics will handle the mechanical and electrical integration of the swappable batteries into its eTrailer systems, creating the prototype eTrailer model for review.

DB Schenker will play a key role in assessing suitable locations to test battery-swapping stations. They will design a forward-looking map of potential sites across Europe.

How will battery swapping impact fleets’ total cost of ownership?

As previously mentioned, the initial acquisition costs for electrified fleets will decrease. This reduction is a significant advantage for fleet operators.

With lower costs, fleet utilisation can increase substantially. Higher utilisation rates allow for more efficient operations.

As a result, there is a strong possibility of lowering the total cost of ownership. This makes the overall solution more attractive for operators looking to optimise their fleets.

Will battery swapping become widely available across Europe?

We firmly believe that battery swapping will support the uptake of electrified heavy-duty vehicles.

Battery swapping is particularly beneficial for large fleets. Setting up battery-swapping stations in depots for electrified fleets makes practical sense.

This initiative marks a significant step towards improving the efficiency and cost-effectiveness of battery charging for heavy-duty vehicles. It will establish a foundation for developing systems that allow for quick and efficient battery swapping. This will increase the range and uptime of electric vehicles in Europe.

About Trailer Dynamics

Founded in 2018, Trailer Dynamics is a technological innovator and system supplier that develops electrified and aerodynamic components allowing semi-trailers to react in real time to the driving behaviour of their coupled tractor unit.

With the support of its integrated electric drive axle, this system allows to significantly reduce diesel tractors’ fuel consumption and carbon emissions or increase the range of battery-electric tractors.